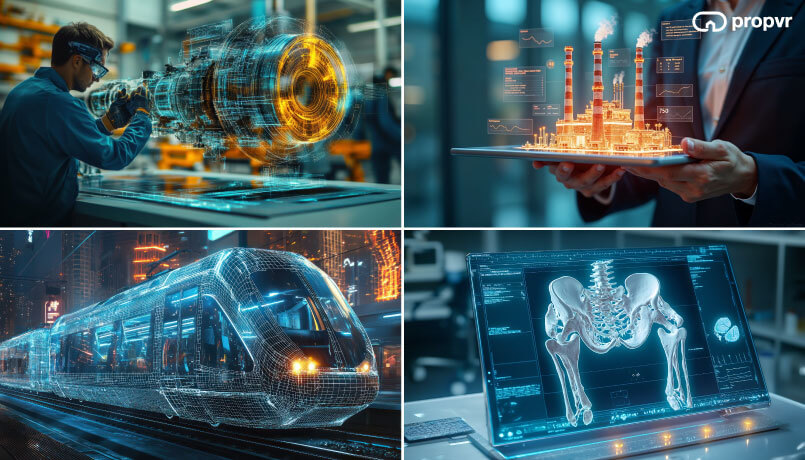

Imagine training as a pilot without ever stepping into a real cockpit, witnessing intricate medical procedures without handling an actual patient, or observing a design’s real-life performance without even beginning its production. Whether you’re from the aerospace industry, a medical professional, or a dedicated engineer, the marvels of digital twin technology can have an exponential impact across sectors. Virtual models created using digital twin technology offer multiple advantages, from enhancing operational efficiency to reducing costs.

This blog delves into 12 industries using this technology to enhance operations. Find popular real-life examples of digital twins across different sectors, from healthcare to education and manufacturing to construction.

1. Digital Twins in Manufacturing

In the manufacturing sector, digital twins allow manufacturers to simulate, monitor, and optimise production processes. The advantages range from improved decision-making to reduced downtime. Using digital twins in the manufacturing industry also assists in rapid prototyping and testing. Integrating technologies like Artificial Intelligence (AI) and machine learning further support predictive maintenance while allowing continuous innovation. Take a look at some popular real-life examples of digital twins in the manufacturing industry below:

- BMW’s digital twins of its manufacturing facilities help support sustainability, simulate production processes and enhance decision-making.

- Pfizer uses digital twinning in its production processes to improve product quality, streamline operations and accelerate time-to-market.

2. Digital Twins in Healthcare

Using digital twins in healthcare helps with accurate diagnosis, equipment care, and enhanced patient support. The technology helps personalise treatment for individual patients by forecasting their body’s response to different treatment strategies. By assisting in virtual clinical trials, digital twinning also expedites the development of biopharmaceutical products while reducing associated costs. Besides, digital twins in healthcare are also used for operational efficiency, assisting in patient flow and resource management. Take a look at some popular real-life examples below:

- Siemens Healthineers uses digital twins for personalised treatment planning in cardiology and oncology.

- Twin Health’s Whole Body Digital Twin can use patient data to manage chronic conditions like diabetes.

- Apollo Hospitals employ AI-driven digital twins to predict disease progression and optimise treatment outcomes.

3. Digital Twins in the Automotive Industry

Using digital twins in the automotive industry simplifies designing and manufacturing stages, simulating these aspects before physical execution, streamlining operations and reducing cost. Additionally, the sensor-collected data facilitates continuous performance monitoring. This helps in the early detection of discrepancies for proactive maintenance. Take a look at some popular real-life examples below:

- Ola Electric used digital twinning to design and build its EV manufacturing plant in Tamil Nadu.

- Marelli, in collaboration with L&T Technology Services, developed a digital twin of the entire electronic architecture, focusing especially on automotive infotainment systems.

- Renault uses digital twins to test designs and fix discrepancies before beginning the actual production of its vehicles.

4. Digital Twins in Smart Cities

A smart city utilises digital twinning to improve lifestyle, infrastructure and resource utilisation. For instance, virtual replicas created using digital twins in smart cities analyse congestion and optimise signals to manage traffic flow. Besides continuous monitoring, these replicas also suggest actions to enhance deteriorating living conditions. Additionally, administrative authorities can use digital twinning to simulate emergencies and plan better disaster management responses.

Take a look at some popular real-life use case scenarios below:

- The Survey of India employed digital twin technology to improve planning, policymaking, and disaster management in cities like Ayodhya, Mumbai, Kanpur, etc.

- Genesys International has been commissioned to develop geospatial 3D digital twins for major Indian cities to encourage sustainable urban design.

- Virtual Singapore is the world’s most advanced city-scale digital twin, designed to enhance urban planning, disaster management, and sustainability efforts.

5. Digital Twins in Energy

Digital twins can help minimise risk and loss in a financially volatile industry like this. The technology can be used to monitor conditions like temperature, pressure, and wind speed. Power generation can simulate the performance of turbines, solar panels, and other equipment. Further, this technology in smart grids helps emulate energy distribution networks for better reliability and renewable energy usage.

Take a look at some popular real-life scenarios of using digital twins in the energy sector below:

- Hitachi’s implementation of digital twin technology in India’s wind farms has enhanced remote monitoring, predictive maintenance and operational optimisation.

- British Petroleum’s (BP) APEX digital twin maps oil and gas production in the North Sea, ultimately reducing unwanted emissions.

- Chevron utilises digital twin technology for better reservoir management, drilling and production optimisation.

6. Digital Twins in Retail

The retail industry has emerged as one of the biggest beneficiaries of digital twin technology. From designing stores to monitoring inventory, improving customer experience to managing supply chains, digital twins in retail offer exceptional utility. The sensor-collected data helps make informed decisions, reduce wastage and minimise cost. Further, it can also help retailers analyse market trends and customer preferences. Take a look at some popular uses of digital twins in the retail world below:

- Retail giant Walmart creates digital twins of stores for over 1,700 locations. These helped minimise inventory shortages and enhance customer experience.

- Lowe’s Innovation Labs developed digital twins of its stores, integrating spatial data with sensor-collected information. The result was better visualisation of store layouts, traffic tracking, optimised workflow and more.

7. Digital Twins in Agriculture

Digital twins enable the reproduction of the entire agricultural setup, including fields, crops, livestock, machinery and other elements. These replicas can help track soil health, expected yield, farm operations and more. Using digital twins in agriculture also helps monitor weather uncertainties, food quality, machinery and livestock. From productivity to efficiency, transformative results are achieved by using digital twins in the agriculture industry. Explore some popular real-life examples below:

- Researchers in South Korea created a digital twin for Mandarin orchards using data collected from across Jeju Island. The virtual model allowed a detailed analysis of crop performance while optimising the yield.

- Microsoft’s Azure FarmBeats provides actionable insights to farmers using IoT sensors and AI-powered digital twins.

8. Digital Twins in Transportation

Using digital twins in transportation helps analyse transport infrastructure (roads, bridges, etc.) under varying conditions. In urban areas, these allow engineers to test their designs virtually before executing them and attain higher precision. In logistics, advantages like route planning and fuel saving enhance truck operations. Further, automobile manufacturers also use digital twins to test, perfect and optimise their designs. Take a look at some popular examples below:

- Ford is widely known for using digital twinning to build autonomous vehicles. The technology allows for the simulation and testing of self-driving algorithms in diverse driving scenarios.

- Singapore’s Land Transport Authority (LTA) created a digital twin of its Mass Rapid Transit (MRT) system to enhance maintenance, reduce downtime and improve passenger experience.

- Transport for London (TfL) uses digital twins to simulate real-life traffic conditions, reducing congestion and maintenance expenditures.

9. Digital Twins in Construction

From the initial steps of designing to the final stages of execution, digital twins can be used throughout the construction process. Using digital twins in construction help engineers detect structural weaknesses, material strength and energy requirements. Additionally, real-time monitoring of buildings helps predict maintenance needs and avoid costly repairs. Data-driven models were created using digital twinning to integrate information from IoT sensors, building information modeling (BIM), and AI-powered analytics. Take a look at their workings through popular real-life examples below:

- The Shard building in London used digital twinning, merging intricate architectural designs with structural simulations to achieve greater construction precision.

- London’s famous Crossrail Project visualised the outcome using digital twin technology. Monitoring progress and identifying issues resulted in better resource utilisation with minimum wastage.

- A virtual replica of China’s Weihai Port was created for health monitoring, ergonomic risk assessment and predictive maintenance.

10. Digital Twins in Aerospace

The aerospace industry uses digital twinning to enhance aircraft designs, optimise fuel efficiency and predict maintenance needs. Simulating various scenarios helps improve aerodynamics and increase safety. Digital twins in the aerospace industry are also heavily used for training purposes. Simulation of complex real-life situations helps train pilots and crew for emergencies and better decision-making. Take a look at some popular real-life examples below:

- Boeing extensively used digital twin technology to develop the 787 Dreamliner, creating virtual replicas for design optimisation and monitoring data for enhanced performance.

- Airbus’s digital twin technology has helped reduce fuel consumption, improve monitoring, and predict maintenance needs for the A350 XWB.

- Rolls-Royce’s IntelligentEngine program creates digital twins of every aircraft engine they produce for enhanced monitoring and maintenance.

11. Digital Twins in Education

Digital twins provide more interactive and immersive learning methods in the education sector. The technology helps create digital models of classrooms, campuses, and learning processes. Digital twinning, especially in fields like medicine and engineering, can provide a hands-on experience for complex theoretical concepts. Additionally, institutions can use the technology to monitor everything from infrastructure to resource allocation. Explore some popular real-life usage of digital twins in the education sector below:

- Siemens’ virtual learning platforms use digital twins that emulate real-life machinery, providing a practical learning experience without physical equipment.

- The University of Wisconsin-Milwaukee’s Connected Systems Institute used digital twining to create a Manufacturing Test Bed, which offered students first-hand experience with automated manufacturing systems.

- Arizona State University (ASU) plans to use ASUniverse, the digital twin of its Tempe campus, to offer immersive campus tours, virtual event participation, and more.

12. Digital Twins in Environmental Monitoring

From scientists to policymakers, insights gained from virtual replicas of ecosystems are helping address environmental concerns faster than before. The technology helps simulate environmental changes, assess risks and develop proactive solutions. Governments and organisations also use it for resource management, disaster preparedness and conservation efforts. Take a look at some real-life use-case scenarios below:

- The Dutch city of Rotterdam utilised a digital twin of their town for flood risk analysis, infrastructure resilience planning, climate scenario modelling, and emergency preparedness.

- The popular 3D model Virtual Singapore uses real-time topographical data for urban planning, disaster management and environmental monitoring.

- The European Union’s Destination Earth (DestinE) project aims to develop a highly accurate digital twin of Earth to model, monitor, and simulate natural phenomena and human activities.

Summing Up

Digital twinning’s industry-wide rise is a pivotal development towards data-backed decision-making. The technology’s power to simulate, predict, and optimise makes it a transformative tool for multiple sectors. Industries as diverse as healthcare and retail and as complex as energy and aerospace are using it in unique ways. As we move towards deeper digital twin integration, advantages like resource management, waste reduction, and increased safety continue simplifying operations.

FAQs

1. What role do digital twins play in the automotive industry?

Digital twins help design, test, and optimise vehicle performance before production. This reduces cost, improves safety, and enables predictive maintenance.

2. How are digital twins used in energy management?

Digital twins simulate power grids, wind farms and oil refineries to optimise energy production and distribution.

3. Can digital twins improve agricultural practices?

Digital twins can model aspects like soil health, crop growth, and livestock conditions. They offer advantages like yield control, resource management, and precision farming.

4. How are digital twins benefiting transportation systems?

Digital twins are used to check infrastructural strength and manage traffic flow. They also improve logistics by enhancing route planning and fuel efficiency.

5. What are the advantages of using digital twins in construction?

Using digital twins in construction offers advantages such as real-time monitoring, material testing, resource optimisation, cost reduction, and more.

6. In what ways are digital twins used in retail?

The use of digital twins in the retail world helps improve the customer experience. The technology also helps with layout optimisation, inventory management, and supply chain tracking.

7. How do digital twins enhance smart cities?

Digital models of cities are widely used for urban planning, traffic management and environmental monitoring. These help with resource allocation and emergency response strategy.

8. What are the uses of digital twins in environmental monitoring?

Digital twins can aid conservation and risk management. The technology can simulate climate patterns, track pollution levels, and predict natural disasters.

9. How do digital twins contribute to aerospace?

Digital twins are used in the aerospace industry to simulate real-world conditions and assist in designing, testing, and maintaining aircraft. They are also heavily used for pilot training and predictive maintenance purposes.

10. How do digital twins impact education?

Digital twins help foster immersive learning environments for students. Digital replicas of real-world systems provide hands-on learning, especially for fields like engineering, medicine and manufacturing.