Transforming Maintenance Processes For Timely Repairs And Efficient Asset Management

Introduction:

Effective maintenance processes are essential for ensuring the reliability and longevity of airport assets. Streamlining maintenance processes through real-time updating of work orders and leveraging digital twin platforms offers a solution to improve efficiency and asset management. This case study explores how airports can optimize maintenance operations by integrating real-time work order updates and task management within a digital twin platform.

Scenario Analysis:

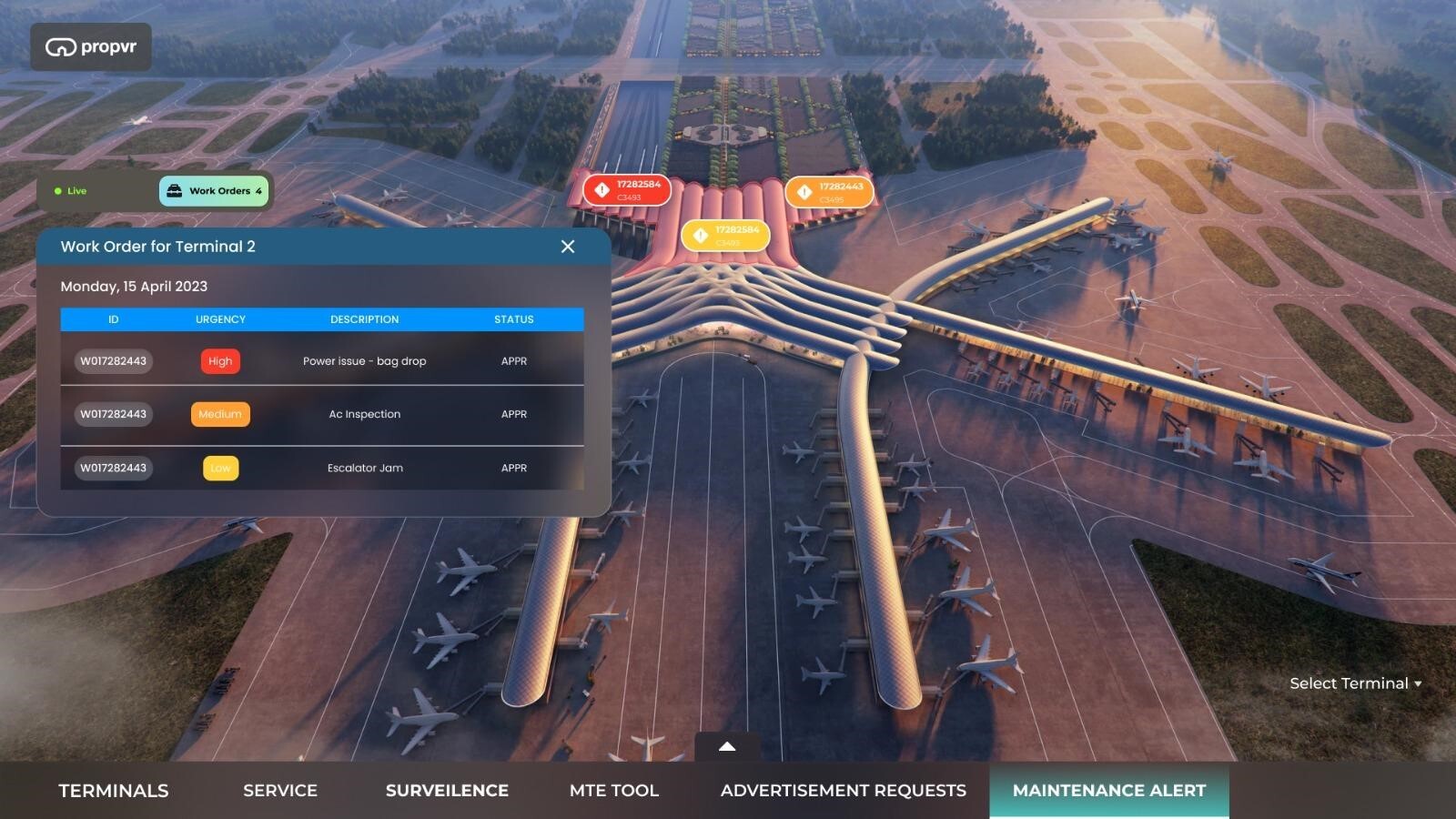

An airport seeks to enhance its maintenance processes to ensure timely repairs and efficient asset management. Implementing a digital twin platform for maintenance operations, the airport integrates real-time updating of work orders, labour hours tracking, and task completion status monitoring. Maintenance personnel access the digital twin platform via mobile devices or tablets, enabling seamless communication and collaboration.

When maintenance tasks are identified, work orders are generated automatically within the digital twin platform. Maintenance technicians receive real-time notifications and updates on their mobile devices, allowing them to view assigned tasks, track progress, and update task status directly within the platform. Labour hours are logged in real-time, providing accurate data on resource utilization and efficiency.

Product Integration and Benefits:

Integrated with the airport's maintenance management system, the digital twin platform provides a centralized hub for managing maintenance operations. Real-time updating of work orders and task management capabilities streamline maintenance processes, reducing response times and improving asset uptime.

The benefits of streamlining maintenance processes through real-time work order updates are significant. By enabling maintenance technicians to update task status and labor hours directly within the platform, airports improve transparency, accountability, and communication across maintenance teams. Real-time data insights empower decision-makers to allocate resources effectively, prioritize critical repairs, and optimize maintenance schedules for enhanced asset management.

Moreover, the digital twin platform facilitates proactive maintenance planning and predictive analytics, enabling airports to identify potential issues before they escalate into costly failures. By leveraging real-time data and analytics, airports can implement preventive maintenance strategies, extend asset lifespan, and reduce overall maintenance costs.

Conclusion:

In conclusion, streamlining maintenance processes through real-time work order updates and digital twin platforms offers airports a powerful tool for enhancing efficiency and asset management. By integrating real-time task management capabilities within the digital twin platform, airports can optimize maintenance operations, improve asset uptime, and reduce maintenance costs.

As airports continue to invest in digital transformation initiatives and predictive maintenance technologies, the future of maintenance processes is characterized by agility, transparency, and data-driven decision-making. Real-time updating of work orders within a digital twin platform empowers maintenance teams to collaborate effectively, respond promptly to maintenance needs, and ensure the reliability and longevity of airport assets.